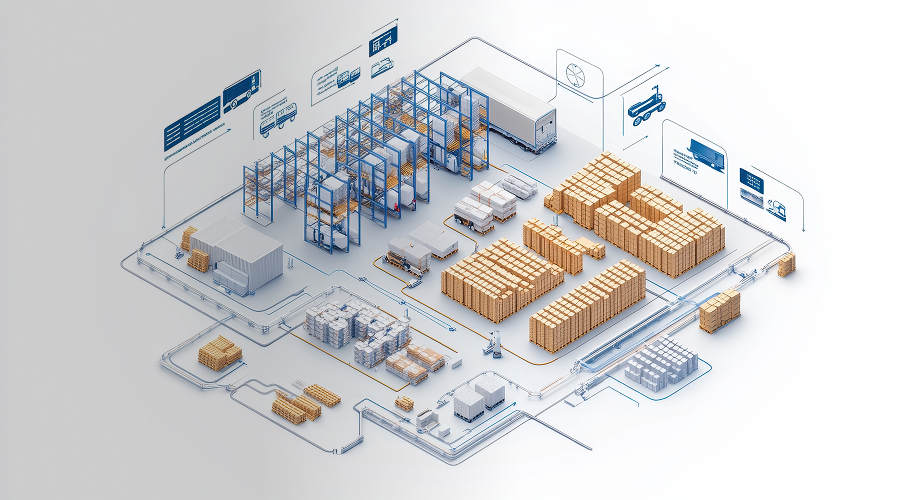

Warehouse Consulting Services for Layout, Optimization & Material Handling Strategy

Practical consulting, built around a plan you can execute

When to Bring in a Warehouse Consultant

When a warehouse is under pressure, small issues stack up fast: longer travel, missed cutoffs, and more rework. Our warehouse consulting services help Warehouse Managers and Operations Directors improve flow, increase throughput, and use space better while keeping safety in focus.

Bring in a warehouse consultant when you need clear answers and a practical path forward. Common triggers include:

- Growth that outpaces your current layout or storage plan

- A changing SKU mix: more eaches, odd sizes, kitting, or returns

- Congestion in receiving, replenishment, pack, or shipping

- Adding racking, conveyors, or automation

- Moving buildings, expanding, or consolidating sites

- Safety concerns like repeated rack hits or near-misses

AWARD WINNING

SERVICE PROVIDER

What We Help You Improve

Warehouse workflow optimization works best when it ties to measurable outcomes. We focus on levers that move performance in a distribution center layout:

- Space and storage density

- Travel time and traffic flow

- Throughput improvement and smoother execution

- Pick accuracy and fewer exceptions

- Safer routes and higher uptime

Warehouse Consulting Services We Provide

Tailored to your operation, your data, and your constraints.

We build or refine layouts that reduce congestion and support the way product should move.

We map current-state and future-state flows from receiving through shipping. Then we remove rework, reduce handoffs, and tighten standards so the process is easier to repeat.

We group SKUs by velocity, cube, and handling needs, then recommend slotting rules and storage strategies that fit your order profile. We also estimate what your facility can store and process today, plus what changes as volume shifts.

Material handling consulting is not about chasing shiny equipment. It’s about matching the right tools to the job. We recommend practical options for lift trucks, conveyors, pick aids, carts, shelving, racking, mezzanines, and safety protection, with attention to uptime and changeover needs.

This is where warehouse optimization consulting turns into real change. You get a plan you can run. If you want, we can support you through sourcing and install coordination so improvements stick.

You should leave the engagement with clear outputs your team can act on.

Deliverables You Can Use Immediately Include:

If you share volume, labor cost, and handling data, we can also model ROI and payback to compare options.

Layout concepts (2D and, when helpful, 3D) with key zones

Process maps for current-state and future-state workflows

A phased implementation plan that minimizes disruption

Recommendations for storage and material handling equipment, with “what and why”

What affects cost and timeline?

These factors usually drive effort and lead time:

Facility size and operational complexity

Data availability and quality

How many options you want evaluated

Equipment and install lead times (when execution is included)

We keep the work structured and easy to follow, especially for engineering teams that need clean inputs and clear decisions.

Our Process

1) Discovery and goal alignment

We confirm objectives, constraints, timelines, and success metrics.

2) Site walk and data review

We observe real workflows on the floor, then align findings with your data.

3) Design options

We present options with tradeoffs, so you can choose what fits your budget and disruption tolerance.

4) Recommendations and implementation plan

We translate the chosen direction into layout details, process changes, and a step-by-step rollout.

5) Implementation support

If you want help executing, we stay involved to answer questions, coordinate with install teams, and adjust based on what the floor teaches us.

Why Choose Warehouse Cubed

Warehouse Cubed combines a consultant’s perspective with an integrator’s follow-through. That means you get recommendations that work in the real world, not just on paper.

- Practical designs built around your processes and equipment

- Safety-aware layouts that reduce cross-traffic and protect people and product

- Clear documentation that supports internal approvals

- Optional support through sourcing and implementation

Take the First Step Toward a More Efficient Warehouse

Ready to Improve Flow, Throughput, and Space?

If you’re seeing congestion, long travel paths, or inconsistent performance, the fastest way to get clarity is a focused consulting engagement. We’ll review your data, walk the operation, and deliver a plan you can execute, including layout options, process changes, and a material handling strategy that fits your constraints.